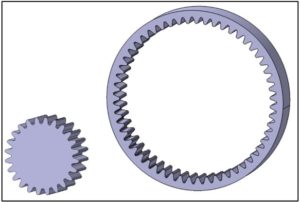

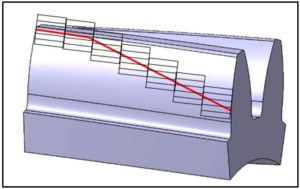

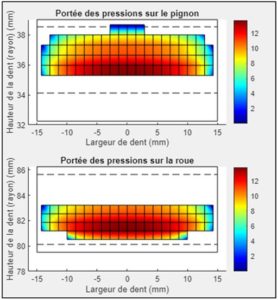

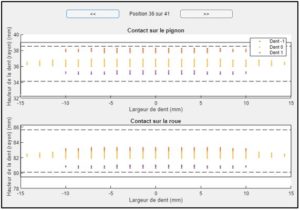

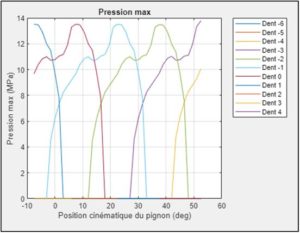

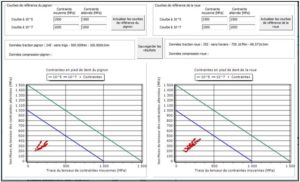

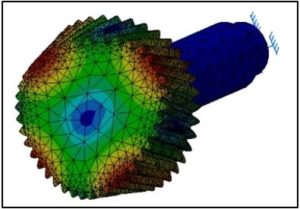

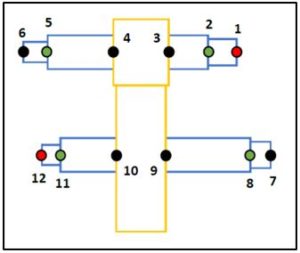

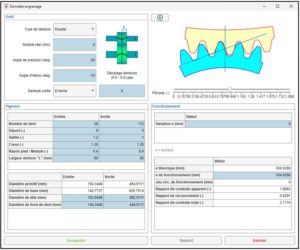

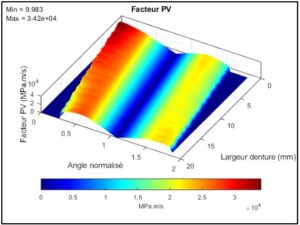

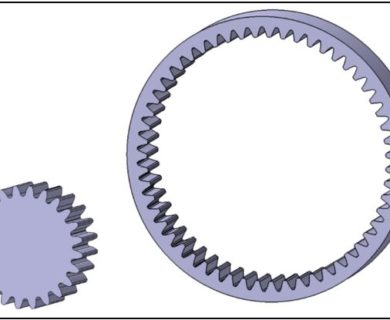

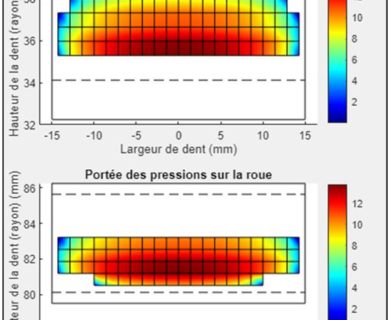

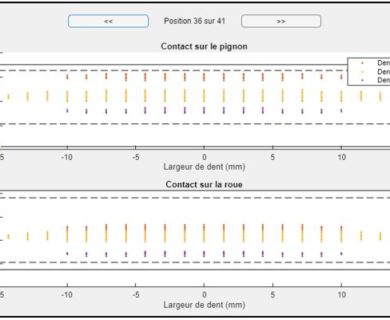

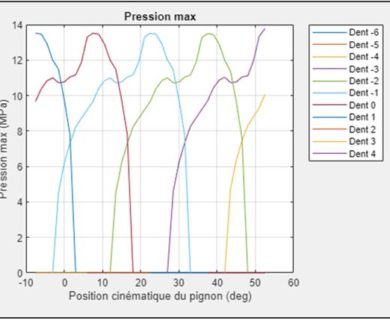

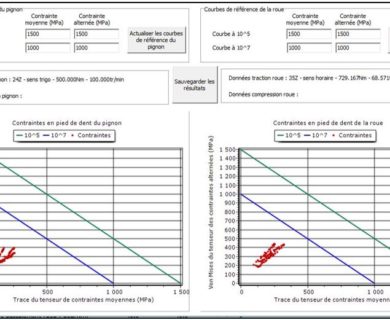

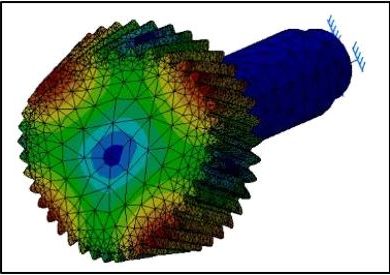

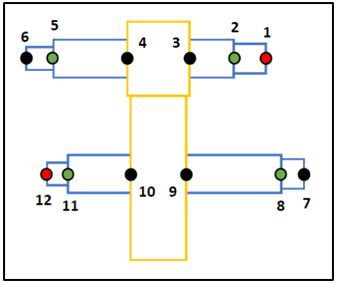

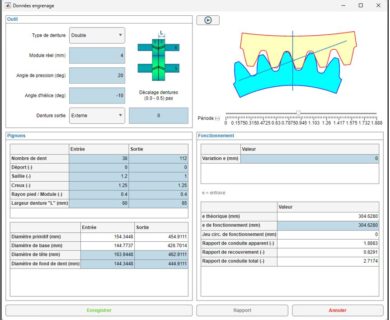

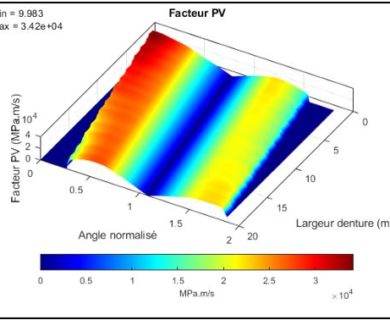

GearDim and Cylam are semi-analytical calculation codes designed to predict the quasi-static behaviors of external and internal cylindrical gears, metal or plastic (for GearDim). GearDim is developed by Mecalam. Cylam is co-developed with Safran and the LaMCoS laboratory of INSA Lyon.

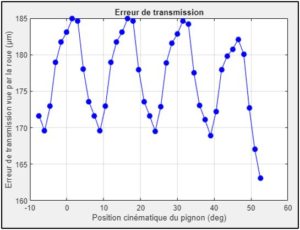

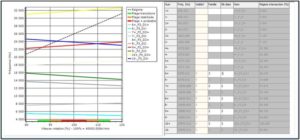

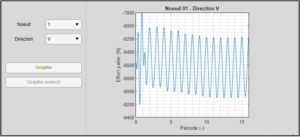

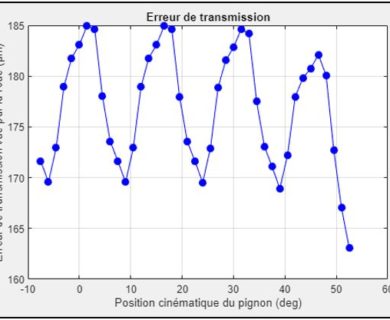

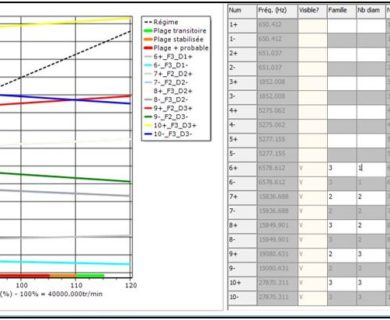

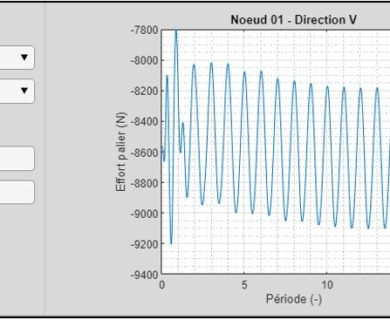

VSA is a semi-analytical calculation code designed to predict the dynamic behaviors of external and internal cylindrical gears. VSA is co-developed with the LaMCoS laboratory of INSA Lyon.