Spiralam is a semi-analytical calculation code designed to predict the quasi-static behavior of spiral bevel gears. Spiralam is co-developed with Safran and the LaMCoS laboratory of INSA Lyon.

Spiralam

Capabilities

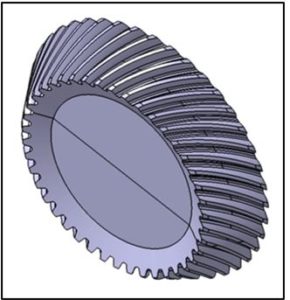

- Import of Gleason or Klingelnberg geometries (meshes or point mapping)

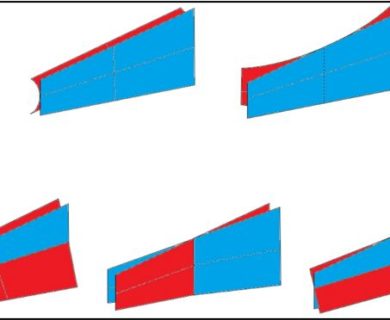

- Micro-geometry (crowning, pressure and spiral angle differences, etc.)

- Manufacturing errors (import of measurement files)

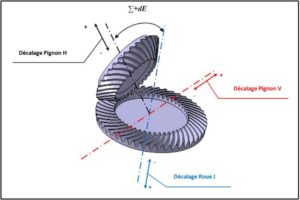

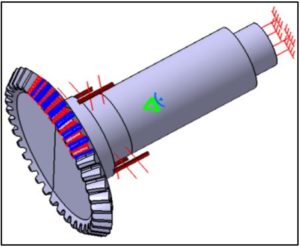

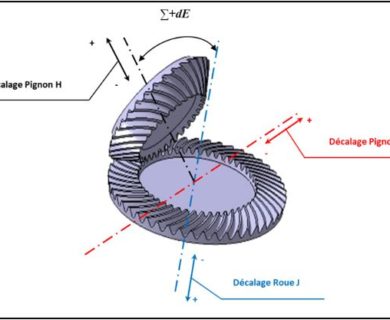

- Misalignments

- Teeth coupling

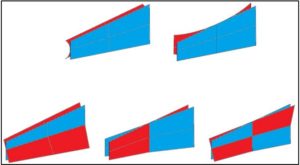

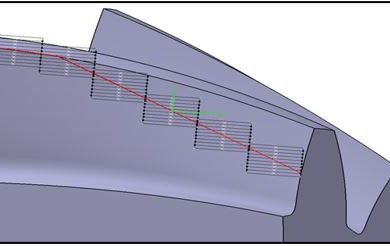

- Parallel contact planes on all teeth

- Mesh slipped around potential contact lines (outside the action plane)

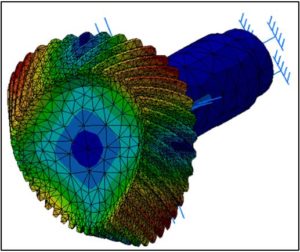

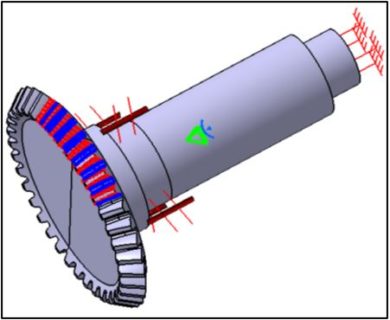

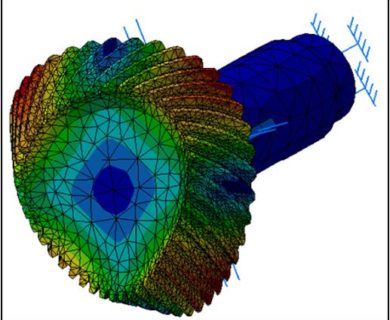

- Structural flexibility (shafts, webs) taken into account through preliminary FE calculations

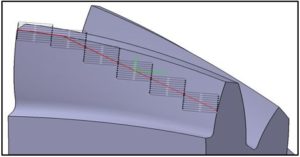

- Tooth bending : mixed FE/analytical influence coefficients method (normal contact effects only)

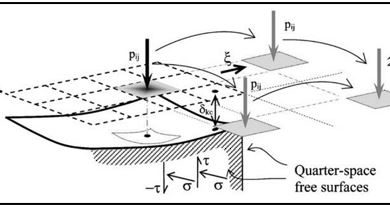

- Contact deformations: simplified Boussinesq and Cerruti analytical formulations (normal contact effects only)

- Mirror method to avoid numerical edge effects

- Non-loaded contact paths

- Non-loaded contact fields

- Non-loaded kinematic error

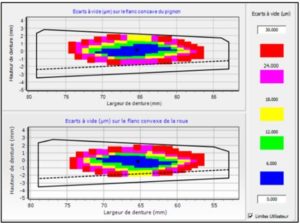

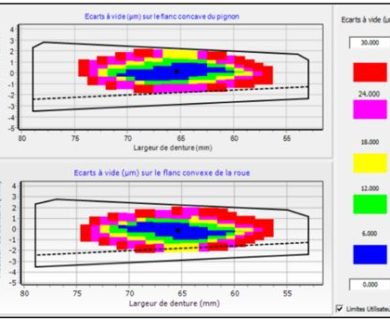

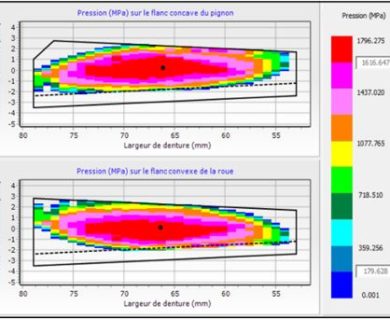

- Operating gaps

- Tooth root gaps

- Slip speeds

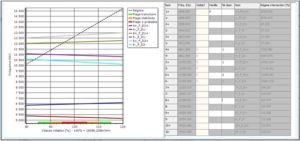

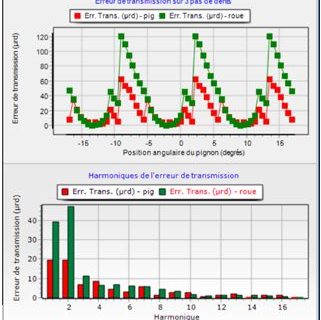

- Loaded transmission error

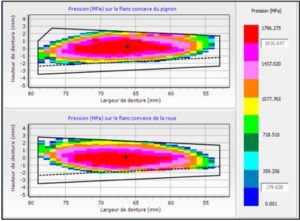

- Pressure fields

- PV and PVT Almen factors

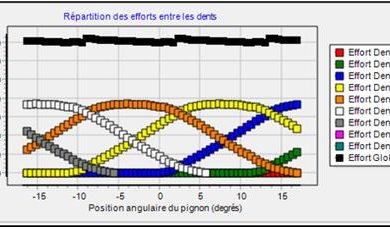

- Load distribution between teeth

- Stiffness

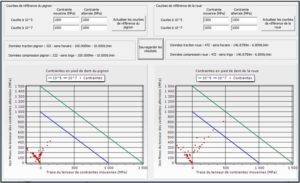

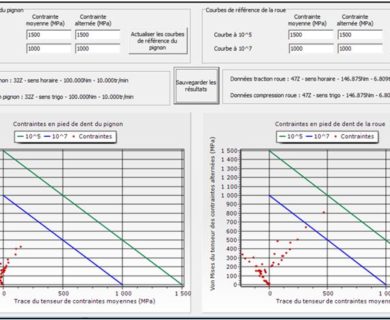

- Tooth root stress fields

- Haigh diagrams

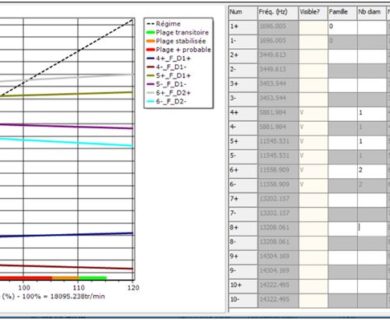

- No-load modal analysis

- Loads export for structural stresses

- Calculation of bearing forces (analytical modeling)