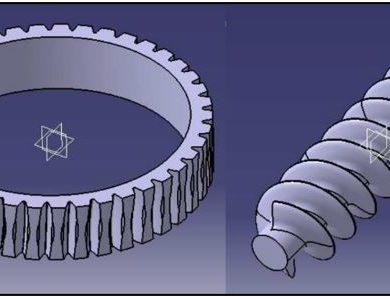

Rouvis is a semi-analytical calculation code designed to predict the quasi-static behavior of rack and pinion gears. Rouvis is co-developed with Jtekt Europe and the LaMCoS laboratory of INSA Lyon.

Rouvis

Capabilities

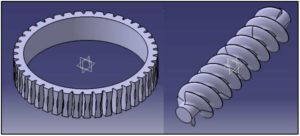

- ZI or ZK screw profile

- Wheel cut by a hob

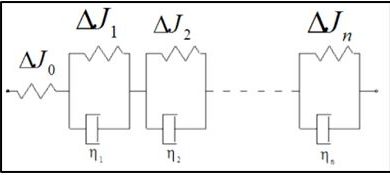

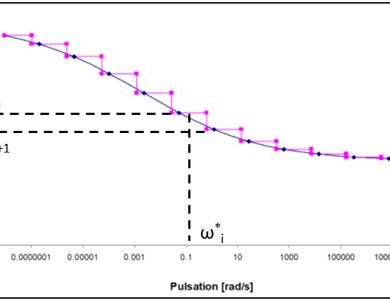

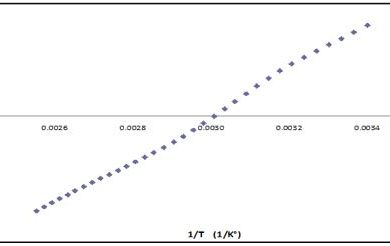

- Metallic screw (considered to be non-deformable), plastic wheel (viscoelasticity considered)

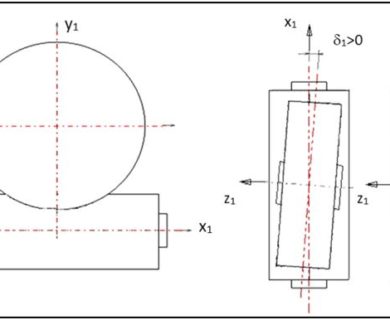

- Misalignments

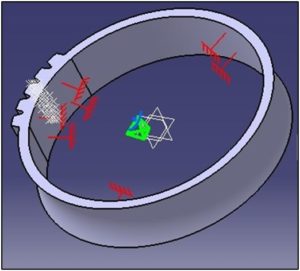

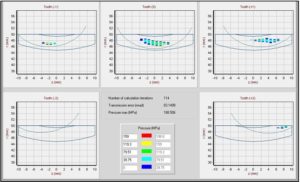

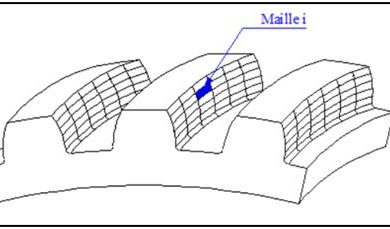

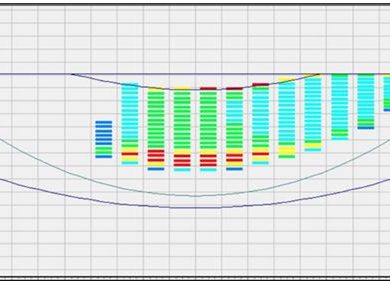

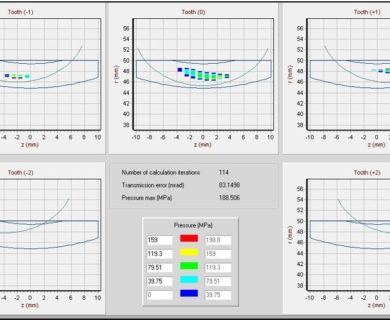

- The entire tooth flank of the wheel is meshed (7 teeth analyzed)

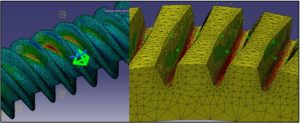

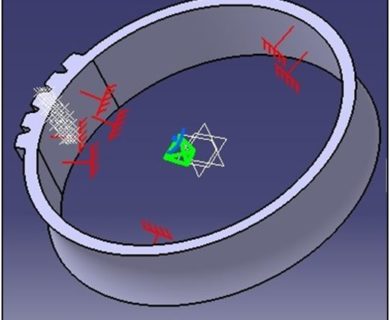

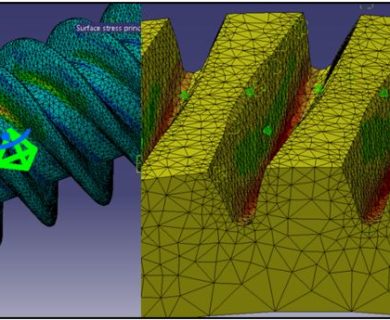

- Structural flexibility taken into account by preliminary FE calculations

- Tooth bending : mixed FE/analytical influence coefficients method

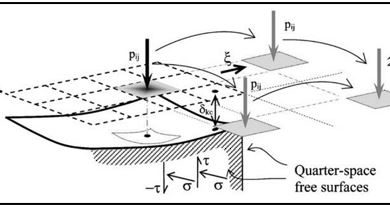

- Contact deformations: generalised Boussinesq and Cerruti analytical formulations (normal and tangential contact effects are considered)

- Mirror method to avoid numerical edge effects

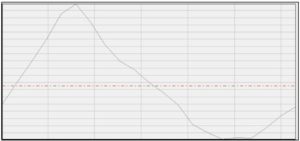

- Non-loaded kinematic error

- Backlash

- Slip speeds

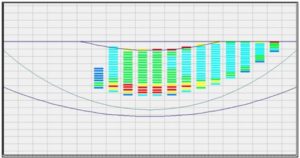

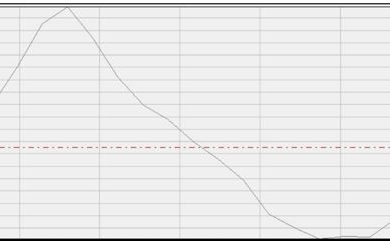

- Loaded transmission error

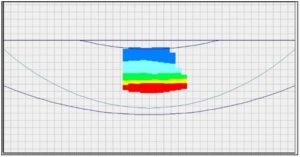

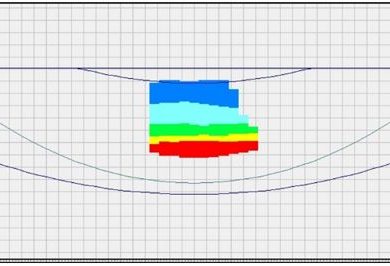

- Loaded contact lines

- Pressure fields

- PV Almen factors

- Stiffness

- Tooth root stress fields

- Loads export for structural stresses

- Metal-to-metal contact (bronze wheel)

- Consideration of screw flexibility